With air leakage a key determinant of a building’s energy cost, occupant comfort and service life, it makes good sense to design effective, airtight, building envelopes. Flashing is an important consideration in maintaining air tightness. With all the different types of flashing tapes available, product knowledge is essential. Multi-layer Polyethylene backing, coated with Acrylic adhesive flashing tape, has proven in both standard and manufacturer testing to have superior performance over all other forms of flashing tape. This superior performance shows in all aspects of durability, including the ability to stand up to severe temperature and weather conditions without degradation. While a seemingly small concern in the overall construction process, the right flashing tape can add up to significant advantages for both builders and users of today’s home. Let’s see why the 505-series Flashing tape is the product to choose to assure long term job site performance.

• Why Multi -layer Polyethylene backing

When it comes to the backing of a flashing tape, three critical characteristics are required in order to provide optimal, long term performance: UV resistance, flexibility (conforming to all shapes and materials) and puncture resistance. The multi-layer polyethylene film we are using for the 505-series was designed to meet these three characteristics. In fact, our 505-series offers unmatched performance, matching and/or exceeding the requirements of AAMA 711-13 Type A, Level 2.

• UV cured Acrylic Adhesive

• UV cured Acrylic Adhesive

The formulation of our UV cured Acrylic Adhesive has been designed to provide exceptional adhesion level and holding power on a variety of substrates including different house wrap materials, vapour barrier film, OSB, aluminum, vinyl and plywood.

• Review of the different Adhesive System used for Flashing Tape

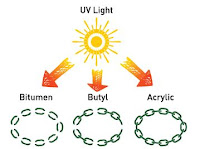

There are basically three adhesive systems used for Flashing Tapes; Bitumen (asphalt) based, Butyl based and Acrylic based.

Bitumen (asphalt) based adhesive: Asphalt tapes are made from modified bitumen, similar to rubberized asphalt, commonly found in eaves flashing. Bitumen asphalt based adhesive flashing tapes have several drawbacks. They are messy to install, and their durability is often of questionable quality. A liquid primer coat may be required to achieve full bond with many substrates, such as oriented strand board (OSB) and concrete. The Flashing products made using bitumen adhesive also have a poor temperature performance range; they often start to lose stickiness at around 50F (10C) and have problems holding below 40F (3C). Problematic application also applies when bitumen asphalt tape is subjected to high temperature or prolonged direct sunlight the adhesive will soften, making the tape detach from the substrate.

Butyl based rubber adhesive: Butyl based rubber (or elastomer) is a synthetic rubber. It is impermeable to air and used in many applications requiring an airtight seal. Butyl based adhesive provides an expanded temperature range (application and resistance) and greater durability than asphalt-based adhesive. It provides a better bond to surfaces, is more flexible in cold weather and is more stable at high temperature than asphalt-based adhesive.

Acrylic based adhesive: Acrylic based adhesive is engineered for superior durability, adhesion and UV resistance than both Asphalt and Butyl based adhesive products. Tuck’s acrylic adhesive is based on a purely acrylic system, providing exceptional characteristics over acrylic water-based or solvent-based systems. Tuck acrylic adhesive formulation forms a strong adhesive bond at a wide temperature range and is formulated to flow into the surface it is applied on. This helps the Tuck Flashing tape to wet out well, flowing into surface inconsistencies to produce a permanent bond. The result is a superior, long lasting seal that is considerably stronger than traditional asphalt and butyl adhesive systems.

Acrylic based adhesive: Acrylic based adhesive is engineered for superior durability, adhesion and UV resistance than both Asphalt and Butyl based adhesive products. Tuck’s acrylic adhesive is based on a purely acrylic system, providing exceptional characteristics over acrylic water-based or solvent-based systems. Tuck acrylic adhesive formulation forms a strong adhesive bond at a wide temperature range and is formulated to flow into the surface it is applied on. This helps the Tuck Flashing tape to wet out well, flowing into surface inconsistencies to produce a permanent bond. The result is a superior, long lasting seal that is considerably stronger than traditional asphalt and butyl adhesive systems.• Acrylic adhesive – Why does it provide superior performance

Viscoelasticity

Viscoelasticity

Because acrylic is viscoelastic, it acts simultaneously as both liquid (viscous part) and solid (elastic part). Its’ viscous properties allow it to flow into small surface cracks and unevenness to form a strong bond. Its’ elastic nature means it possesses the adhesive strength necessary to preserve the bond. The viscoelasticity of Tuck’s Acrylic adhesive formulation exhibit traits of both liquids and solids enabling superior initial adhesion. It also gives 505 Flashing tape the ability to dissipate stresses and resist compression, deformation and flattening.

Heat and UV Resistance

Heat and ultraviolet light are two key factors that degrade tape life. The Tuck Acrylic adhesive system resists both heat and UV sunlight far better than asphalt and butyl-based adhesive systems. The cross-linked polymer chains employed in the Tuck Acrylic adhesive, create extremely strong molecular bonds that withstand a wide range of temperatures, also dissipates light energy, which can break the bonds in asphalt and butyl-based adhesive.